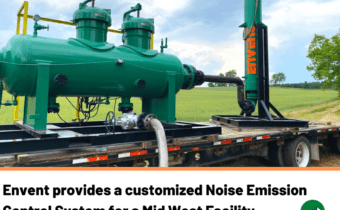

Challenge A customer in the Midwest needed to reduce noise coming from a natural gas pipeline blowdown. Pipeline blowdown operations can be very loud have the potential to disrupt the immediate area. The gaseous contents of the pipeline are at high pressure and when that pressure is under controlled release, creates an unpleasant rushing sound. ENVENT was called upon to assist […]