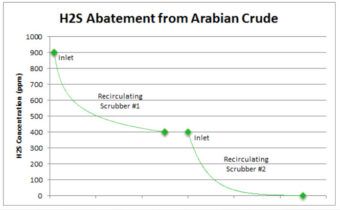

Challenge A customer was facing EPA fines in the tens of thousands of dollars per day for the release of H2S and VOC’s to atmosphere from a tank not permitted to contain H2S-laden material. The customer reached out to Envent to solve the problem within a short deadline of three months. Solution Envent was […]