Challenge

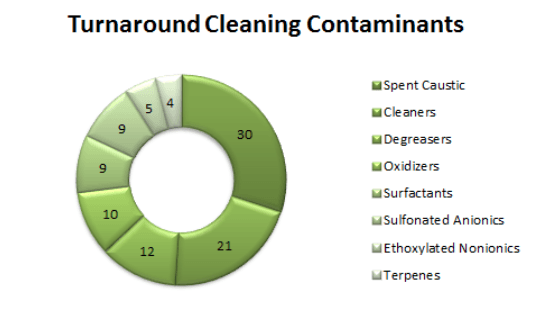

During a scheduled refinery turnaround, multiple units across different locations in the plant were undergoing chemical cleaning operations. The resulting wastewater runoff was collected from these processes and contained a mix of hazardous materials—including spent caustic, industrial cleaners, oxidizers, degreasers, and surfactants.

The wastewater did not meet onsite discharge specifications, and the refinery required a temporary, engineered wastewater containment system that would comply with environmental regulations while supporting tight turnaround timelines.

Solution

Envent Corporation mobilized and managed a temporary wastewater storage and treatment system, which included:

-

200,000 gallons of temporary tank capacity, strategically placed to serve multiple refinery zones

-

A network of carbon scrubber systems, berms, pumps, and heat exchangers to safely manage, contain, and process chemical-laden wastewater

-

Real-time support by experienced field operators and oversight from Envent’s engineering team, ensuring regulatory compliance and effective fluid management throughout the operation

The system was tailored to prevent vapor release, minimize environmental exposure, and handle complex chemical mixtures typical in refinery wastewater treatment.

Benefit

Envent delivered a cost-effective, environmentally friendly, and turnkey water treatment solution that saved the client approximately $150,000. The success of this project highlights Envent’s capabilities in:

-

Mobile water treatment services

-

Refinery wastewater management

-

Custom engineered vapor and water control systems

By applying a systematic, engineered approach, Envent helped the customer avoid costly delays, manage hazardous runoff safely, and maintain full environmental compliance during a critical maintenance window.

Project: Turnaround Support Services Cost Savings: $150,000 Location: Gulf Coast Refinery